By using our site, you acknowledge that you have read and understand our Privacy Policy.

Logix® leverages two industry-leading components for the best energy management systems in the business.

Clarity™ Management Software

Logix Clarity management software for PCs communicates with distributed controllers, graphically displays and logs operating data, and provides for user viewing and alteration of control settings. The software is prized by our customers for intuitive ease of use, sophisticated visualization of the refrigeration system, and powerful data analysis tools.

Learn More

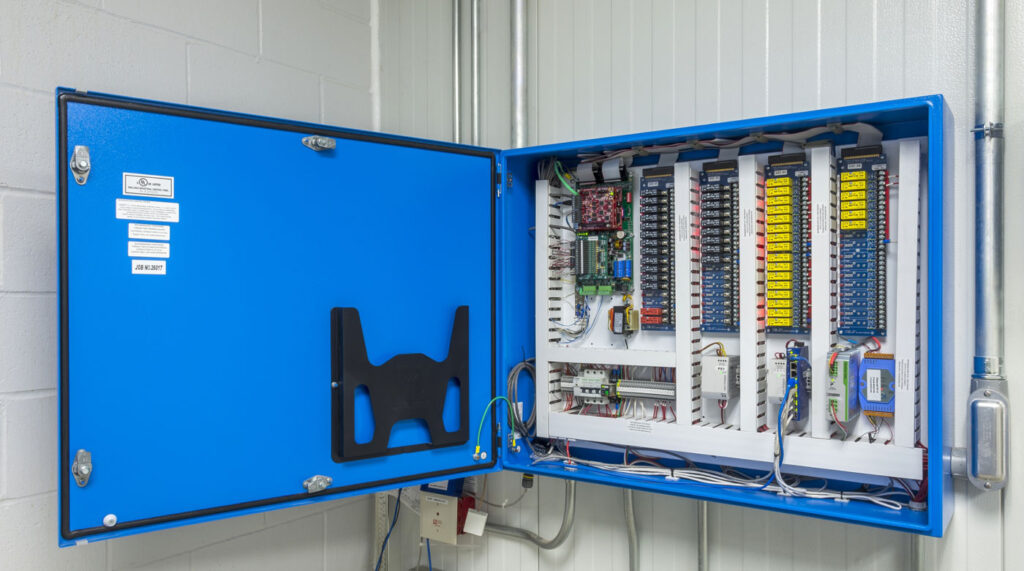

Axiom™ Microprocessor Panels

The industrial-grade Axiom microprocessor panels provide distributed control of compressors, evaporators, condensers, and other mechanical equipment for maximum efficiency and safety.

Learn More

A field-proven Compressor Control System that easily adapts to most compressor designs.

Logix® Screw Compressor Control System (CCS)

An industrial-grade controller featuring a Viewpoint® color graphics status screen, online Help and documentation, powerful ramp start, capacity control options, and much more.

Learn More

Gain real-time visibility into your entire network of facilities.

Pulse IoT cloud-based software

Keep your finger on the pulse of your business with the next-generation remote refrigeration management platform.

Learn More

Agility™ Stand-alone Refrigeration Equipment Controllers

Four different equipment controllers. One stand-alone solution for success.

The industrial-grade Axiom microprocessor panels provide distributed control of compressors, evaporators, condensers, and other mechanical equipment for maximum efficiency and safety.

“Logix has a deep knowledge of all the intricacies of a good refrigeration system in different environments. They’re more than just controls experts - they have good refrigeration management knowledge.”

Alan Burrows, P.E.

Corporate Engineer

Safeway